Thermal oil heating steam generators is to use high temperature thermal oil to heat the water in the drum to create steam generator. It is U-shape tube heating device. When high temperature heat transfer oil flows through the tube, the heat will be released, making the water in the steam generator become saturated steam and these steam could be used.

Table of Contents

Application of Thermal Oil Steam Generators

Thermal Oil Steam Generator can be used with thermal oil heater. Widely applied in food processing, rubber industrial, wood processing, oil production industrial, etc. It can meet the requirement of using one thermal oil heater to get hot thermal oil and steam at the same time which saving a lot of equipment investment and labor cost. It uses the continuous circulated thermal oil to generate steam which can replace the steam boiler.

Advantage Feature:

- The thermal efficiency of thermal oil steam generator is 10% higher than steam boiler.

- Thermal oil steam generator uses heat transfer oil to generate steam, instead of direct flame heating, so it’s more safe and reliable than steam boiler.

- Thermal oil steam generator is more environmentally friendly than steam boiler as it does not generate any exhaust gas or ash. The auxiliary equipment it needs is only a water feed pump.

- Thermal oil steam generator can provide fast steam produce speed and stable steam pressure

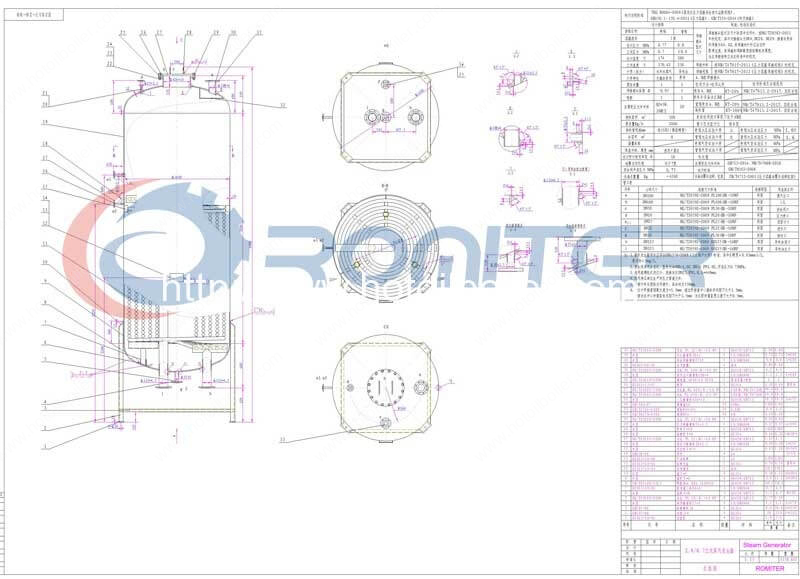

General Drawing of Vertical Thermal Oil Heating Steam Generator

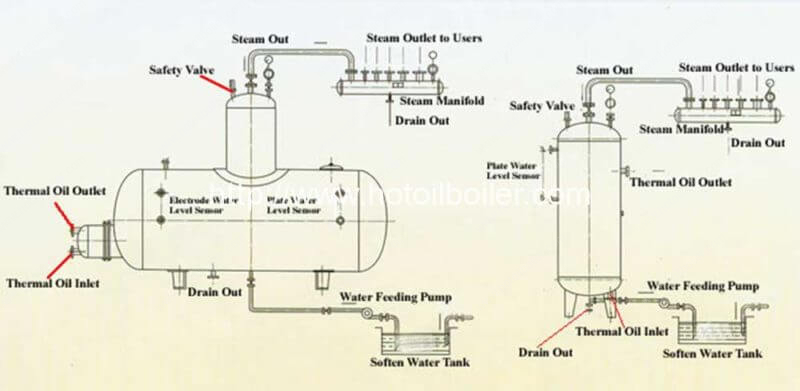

Connection Drawing of Thermal Oil Steam Generators

Parameter Table of Vertical Thermal Oil Heating Steam Generators

| Item | WLE-0.1/0.5 | WLE-0.25/0.7 | WLE-0.5/0.8 | WLE-0.7/0.7 | WLE-1.0/0.7 | WLE-1.5/0.7 | WLE-2.0/0.7 | |

| Vertical | ||||||||

| Evaporation Capacity t/h | 0.1 | 0.2 | 0.5 | 0.7 | 1 | 1.5 | 2 | |

| Design Pressure | 0.55 | 0.77 | 0.88 | 0.77 | 0.77 | 0.77 | 0.77 | |

| Steam Temp. ℃ | 162 | 174 | 179 | 174 | 174 | 174 | 174 | |

| Tube Design Pressure | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | |

| Tube Design Temp. ℃ | 300 | 300 | 300 | 300 | 300 | 300 | 300 | |

| Working | Thermal | Thermal | Thermal | Thermal | Thermal | Thermal | Thermal | |

| Medium | Oil | Oil | Oil | Oil | Oil | Oil | Oil | |

| Heat Exchange Area m2 | 7 | 16 | 25 | 40 | 50 | 70 | 100 | |

| Cubage m3 | 0.55 | 2.5 | 3 | 4.5 | 5.2 | 5.5 | 8 | |

| Pipe. DN | 20 | 50 | 50 | 50 | 50 | 100 | 100 | |

| Dimension | H mm | 2264 | 3255 | 3362 | 4000 | 4102 | 4752 | 5402 |

| φ(mm) | Φ700 | Φ1200 | Φ1300 | Φ1400 | Φ1500 | Φ1500 | Φ1500 | |

| Total | 390 | 1294 | 1790 | 2375 | 2753 | 3415 | 4239 | |

| Weight kg | ||||||||

Thermal Oil Boiler Production Equipment

Factory Visit

Company Profile

Romiter Group Limited are committed to manufacturing and exporting complete enery saving heating equipment, including thermal oil boiler (Thermal fluid heat transfer product), thermal oil steam generator, cryogenic storage Dewar. After many years reach & development, Romiter Group can provide coal fired thermal oil boiler, gas fired thermal oil boiler, diesel fired thermal oil boiler, electric heating thermal oil boiler, coal fired molten salt heater, gas or oil fired molten salt heater and all type liquid gas vacuum cryogenic storage Dewar.